Civil War Ordnance Bureaus

by Philip Leigh

The Confederate and Union War Department Ordnance Bureaus were responsible for supplying their respective field armies with weapons and munitions. The Confederate bureau’s principle challenge was to overcome the handicap of having little domestic manufacturing capacity and to get imports through the Union maritime blockade. Since the Union-loyal states possessed 85% of antebellum America’s factories and had some of the world’s most innovative weapons, the ultimate story of the federal bureau is one of a revolution in firearms designs. When the war started on April 12, 1861 the Confederacy had almost no arms other than what they gained when the component states seized various federal arsenals during secession. Soon after the war started, the federals abandoned and burned the Harpers Ferry Armory. Much of the production equipment, however, was salvaged by the Confederates and moved to the Virginia State Arsenal in Richmond and to Fayetteville, North Carolina. As their capacity was inadequate, Josiah Gorgas Chief of Ordnance sent agents to England to contract for small arms and canon which were imported by blockade runners transporting cotton to Bermuda or the Bahamas and arms and ammunition back to Southern ports such as Wilmington NC. The Ordnance Bureau relied on privately owned ships but also purchased a small fleet of blockade runners. Gorgas was equally focused on the domestic manufacture of weapons, munitions and gunpowder. An assortment of existing foundries, machine shops and railroad repair facilities were quickly put into production to temporarily help meet the immediate surge in demand for small arms. And battlefield capture of federal small arms and canon was also a significant source for the Confederacy. Since gunpowder was produced in few private factories, the Ordnance Bureau organized the construction of a major gunpowder plant in Augusta GA. While charcoal and sulfur were widely available, the third component of gunpowder, niter, was in short supply and most of that used was imported. Lead for bullets and shells and copper for percussion caps were also in short supply and domestically available sources were supplemented by significant imports. Notwithstanding the South’s initial dearth of factories, scarce natural resources, persistent skilled labor shortages and a Union Naval blockade, Josiah Gorgas’s Ordnance Bureau was one of the Confederacy’s success stories. Until the final surrenders, the chief Confederate armies were well supplied with arms and ammunition. When the Army of Northern Virginia surrendered at Appomattox the soldiers had been without food for three days, but each infantryman carried 75 rounds of ammunition. Compared to the Confederacy, the Northern and Union-loyal border states enjoyed considerable industrial capacity. They had 85% of America’s factories and 92% of iron and steel production. More than 80% of America’s small arms manufacturing was centered in the Connecticut River Valley. Three major gunpowder manufacturers were located in the north. The Union Ordnance Department was able to supply the armies largely from domestic sources, although imports were important during the first year-and-a-half of the war. The Chief of Ordnance for the north was General James Ripley. When Ripley became Ordnance Chief shoulder arms were beginning to transition from muzzleloaders to breechloaders, and even repeaters. If Union leaders had taken breech-loading and repeating arms more seriously after Sumter, they might have won the war in two or three years instead of the four required. Lincoln’s first Secretary of War, Simon Cameron, was a political appointee who often deferred to General Ripley’s distrust of new and untried arms. That left the Bureau to concentrate on maximizing production for the .58 caliber Springfield muzzle loading rifle until Ripley was replaced. He did not permit government facilities to make breechloaders of any type. Thus, the only breechloaders that reached the soldiers were made by private industry. Ripley furthermore encroached upon the production capacity for private suppliers by giving them lucrative contracts to instead make Springfields. Those opposing breechloaders argued their faster firing rate would promote ammunition wastage and that they were insufficiently rugged, although single-shot breech loading carbines were favored for mounted units even at the beginning of the war. As the war progressed and breechloaders and repeaters were gradually adopted in the Union cavalry, their superiority became obvious to everyone. When unable to make headway with Ripley, determined officers and private contractors used political connections to force him to order breechloaders. Among those breechloaders and repeaters gradually reaching the Union cavalry were the Sharps, Spencer and Burnside carbines and the Henry (which became the Winchester ’73) rifle. The July 1863 Battle of Gettysburg proved to be a turning point in the breechloader versus muzzle-loader contest. In addition to the firepower advantages enjoyed by John Buford’s single-shot breechloader federal cavalry at the start of the battle, George Custer’s Spencer-equipped cavalry convincingly demonstrated the repeater’s advantages on the third day. In September 1863 General George Ramsay replaced Ripley as chief of the Ordnance Bureau and he in turn was replaced by Alexander Dyer in September 1864 who made it his goal to arm all soldiers with breechloaders and repeaters. As the number of Spencers reaching the soldiers increased and shipments of models using paper and linen cartridges decreased metal cartridges demonstrated their decisive superiority in combat. The Ordnance Bureau might have advantageously settled on a private breechloading rifle design and issued contracts to private manufacturers for the superior weapon. Instead, the relationship between the Bureau and manufacturers was often adversarial, with penalties and cancellations for late deliveries. Inventors like Spencer and Henry received no material assistance or even advice about how to scale production. When Lee surrendered at Appomattox in April 1865 the United States Army had not only won the Civil War, it had finished a revolution in shoulder arms design. The previous month War Secretary Edwin Stanton directed that all federal soldiers be issued breechloaders as soon as they could be delivered.

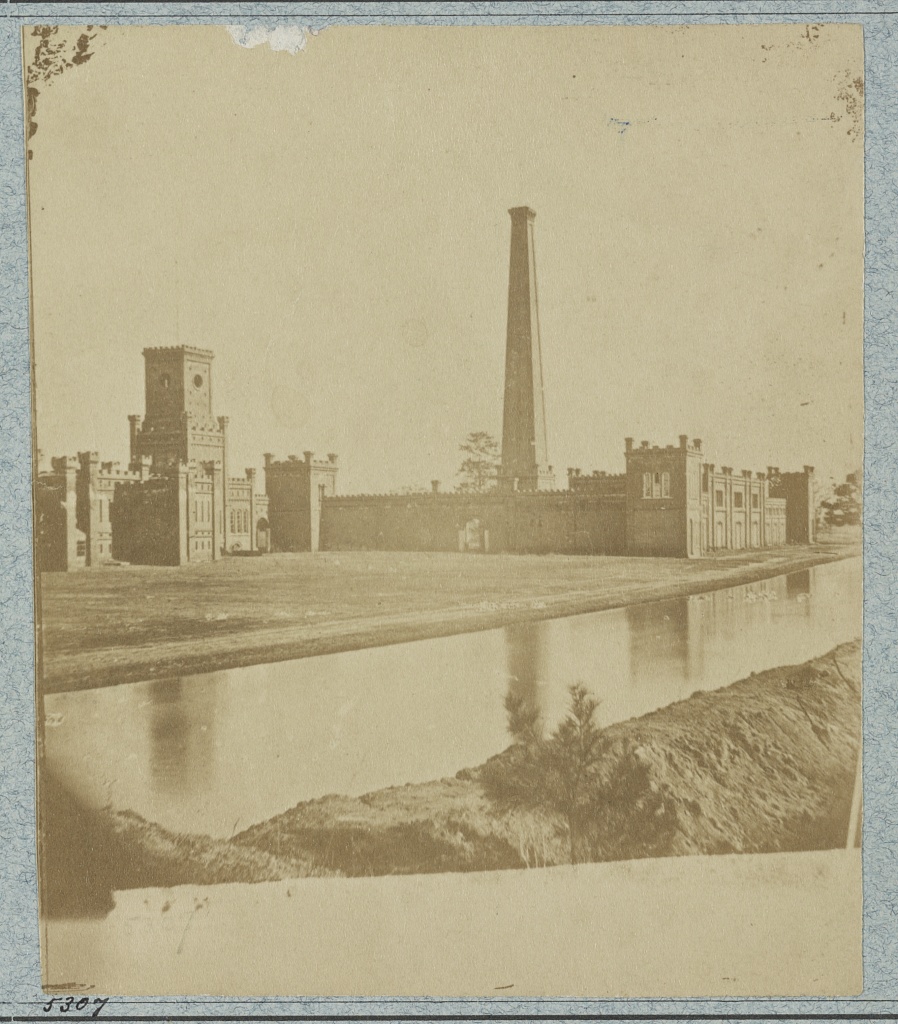

Confederate Powder Works, Augusta, Ga. Photographed between 1861 and 1865, the photograph is half of a stereograph albumen print on card mount, photographer unknown.

Photograph courtesy of the Library of Congress Prints and Photographs Division.

The Confederate and Union War Department Ordnance Bureaus were responsible for supplying their respective field armies with weapons and munitions. The Confederate bureau’s principle challenge was to overcome the handicap of having little domestic manufacturing capacity and to get imports through the Union maritime blockade. Since the Union-loyal states possessed 85% of America’s antebellum factories and had some of the world’s most innovative weapons, the ultimate story of the federal bureau is one of a revolution in shoulder arms design.

Confederate Ordnance

The supply structure of the Confederate War Department is illustrated below. Contributing organizations reported to the Secretary of War. The Commissary General was responsible for providing food while the Quartermaster General supplied such items as clothing, shoes, wagons, tents, and horse harnesses. The Chief of Ordnance supplied weapons and munitions. Although initially a Corps of the Ordnance Bureau, the Niter and Mining Bureau became independent in 1863 to provide chemicals such as saltpeter for the production of gunpowder. It also supplied metals such as lead, iron, and copper for the manufacture of bullets, weapons, and percussion caps, respectively.

President Jefferson Davis appointed Josiah Gorgas as Chief of Ordnance on April 2, 1861, ten days before the shooting started at Fort Sumter. Gorgas was born in 1818 as one of ten children in a rural south-central Pennsylvania family. He graduated sixth in his West Point class of fifty-two in 1841. After graduation, he served at various arsenals before crossing the Atlantic to study European ordnance for twelve months in 1845-46. He re-crossed the Atlantic to participate in the Mexican War in 1847. Thereafter, Gorgas had various ordnance assignments until posted to a small arsenal near Mobile, Alabama where he met his wife, the daughter of a former Alabama governor.

When the Civil War came, he sided with the South and was thereafter estranged from his Pennsylvania family. After the Confederacy moved its capital from Montgomery, Alabama to Richmond, he located the Ordnance Office in the Virginia Armory adjacent to the Tredegar Iron Works on the banks of the James River in June 1861. Tredegar was initially the Confederacy’s only factory capable of producing heavy ordnance. By the end of the war, it had accounted for half the cannon and nearly all the artillery ammunition produced in the Confederacy.[1]

When the war started on April 12, 1861 the Confederacy had almost no arms other than what they gained when the component states seized various federal arsenals during secession. An initial inventory totaled about 100,000 small arms, including pistol and shoulder arms. There were also about seven hundred cannons, most stationed for coastal defense. Many of the weapons were obsolete, and the small arms were of various calibers thereby complicating munitions supply. There was almost no field artillery except for a few dating from the War of 1812 and a few modern pieces belonging to the individual states. Gunpowder was scarce and the supply of percussion caps, used to ignite the gunpowder inside an infantryman’s musket or rifle, was almost non-existent.[2]

Before the war America had two major armories capable of making military firearms. One was in Springfield, Massachusetts and the other in Harpers Ferry, which would become part of Union-loyal West Virginia. Soon after the war started, the federals abandoned and burned the Harpers Ferry Armory. Much of the production equipment, however, was salvaged by the Confederates and moved to the Virginia State Arsenal in Richmond. Although some of the equipment remained in Richmond, most was shipped to Fayetteville, North Carolina. As a result, Richmond and Fayetteville became the Confederacy’s main small arms manufacturing towns. Since Gorgas realized their capacities were inadequate to supply the rapidly growing Confederate armies that resulted from an initial enlistment surge, he promptly turned to imports.

First, he sent Major Caleb Huse to Liverpool to buy British arms. Huse arrived in England on May 10, 1861 before the federals recognized the urgent need to import arms for their armies. Not until they lost the First Battle of Bull Run on July 21, 1861 did Union leaders realize they would need bigger armies, which they could not entirely supply from domestic sources. By arriving first, Huse was able to make the Confederacy the sole international buyer for the output of the London Armory Company that would ultimately ship 70,000 modern rifles across the Atlantic. Although little was available for immediate delivery, Huse made contracts for substantial future deliveries. By the end of 1862 he had purchased a total of 160,000 firearms from various sources as well as some artillery and other ordnance items. In combination with Northern arms collected from battlefields such imports accounted for 90% of Confederate shoulder arms before 1863.[3]

Second, since Huse’s purchases had to slip through the federal blockade, Gorgas began to consider buying blockade runners for the Ordnance Bureau after the C.S.S. Fingal arrived in Savannah in November 1861 with a cargo of over 11,000 rifles and other military stores. A year later he started forming his own fleet because privately operated blockade runners tended to import luxury items instead of ordnance. Eventually, Gorgas would manage a fleet of five government-owned blockade runners, of which the C.S.S. Robert E. Lee was the most famous. She completed twenty-one trips, taking out 7,000 four-hundred-pound cotton bales and returning with ordnance, until captured in November 1863. In Britain the cotton could be sold for gold and prices climbed as high as $1.89 a pound during the war. Due to blockade running, the Carolina ports at Charleston and Wilmington became busier than before the war.[4]

Gorgas mostly operated his runners between St. George, Bermuda and Wilmington, North Carolina. Transatlantic vessels would arrive at St. George from Europe loaded with ordnance and pick up cotton brought by the blockade runners from Wilmington. The blockade runners would then return to Wilmington loaded with ordnance and reload with cotton for repeat round trips. He preferred St. George over transfer points such as Nassau or Havana because Bermuda was far from the Union Navy’s coaling stations, thereby making it difficult for Union blockaders to patrol the island. He preferred Wilmington over Charleston because it was initially less crowded with commercial blockade runners and had two well-guarded inlets.

In 1864 the War Department formed the Bureau of Foreign Supplies to harmonize the overseas purchases of all bureaus such and Ordnance, Commissary and Quartermaster bureaus. It also coordinated the activities of government owned blockade runners and could force privately owned blockade runners to allocate space for government shipments. All told, blockade runners delivered a total of 330,000 small arms for the Ordnance Bureau and 270,000 for the states and private citizens. Cotton exports through the blockade approximated 1,250,000 bales.[5]

The typical blockade runner was 80 feet long, with a 22-foot beam, and propelled by side-mounted paddlewheels that required less draft than a propeller ship. The ships would normally burn nearly smokeless anthracite coal and were painted in dull colors to make them difficult to spot. Hulls rose only a few feet above the waterline. All lights were covered, and some engines were equipped to release steam under water. Even in daylight the stealthiest runners could “scarcely be seen a matter of yards away.”[6]

After initially focusing on imports Gorgas turned his attention to the domestic manufacture of weapons, munitions and gunpowder. An assortment of existing foundries, machine shops and railroad repair facilities were quickly put into production to temporarily help meet the immediate surge in demand for small arms. Among them were plants in Atlanta, Charleston, Columbia, Savannah, Jackson, Memphis, Mobile, Montgomery, Baton Rouge, Little Rock, and San Antonio, mostly producing ammunition for the small arms already in the field, imports, and the firearms manufactured in Fayetteville and Richmond. Others, such as substantial factories in New Orleans and Nashville, had to be abandoned early in the war after they were captured by Union armies.

In addition to the Richmond’s Tredegar Iron Works, Gorgas added cannon foundries at Macon, Columbus, and Augusta, Georgia. Shot and shell for the cannons was produced in Salisbury, Virginia and Montgomery, Alabama. Eventually Selma, Alabama employed 10,000 workers focused on pig iron and heavy ordnance production as well as shipbuilding. Output of the small arms munitions factories typically supplied nearby armies and forts. Thus, Robert E. Lee’s Army of Northern Virginia was chiefly supplied by Richmond and Fayetteville as well as imports through Wilmington. The Army of Tennessee drew ammunition mostly from Augusta, Macon, and Atlanta. Despite constant challenges to find skilled labor and acquire the proper manufacturing equipment, Gorgas made steady progress.[7]

One of the most serious shortages was gunpowder. At the start of the war the Confederacy’s entire supply could sustain barely a month of active military operations. There were only five small privately-owned factories, and none produced more than a few pounds a day. South Carolina and Tennessee each had two while North Carolina had one. Without new production facilities the bulk of the Confederacy’s gunpowder would need to be imported.

As a result, in July 1861 Gorgas and President Davis assigned George Washington Rains to construct a centrally located gunpowder plant large enough “to supply the armies in the field and the artillery of the forts and coastal defenses.” Rains had graduated third in his West Point class a year behind Gorgas. Thereafter, he served in various military posts and married a wealthy New Yorker. Eventually he became president of his father-in-law’s iron manufacturing company where he was awarded patents involving steam engines.

The native North Carolinian returned to the South after the war started. Before the end of his first month of working for Gorgas, Rains settled on Augusta, Georgia as the best location for the powder factory for four reasons. First, it was far from the initial battle fronts in Virginia and Tennessee. Second, the Augusta Canal could reliably provide flowing water to power the plant’s machinery. Built in 1845, the canal was one of the few successful industrial canals in the South. Antebellum town promoters hailed Augusta as “the Lowell of the South,” evoking comparison to the Massachusetts town that had pioneered America’s Industrial Revolution with water powered textile plants. Third, Augusta had good connections to transportation by rail and water. Fourth, during the previous fifteen years Augusta had emerged as a regional industrial center with a pool of skilled labor.[8]

Gunpowder is composed of potassium nitrate (niter or saltpeter), charcoal, and sulfur in the ratios of 15, 3, and 2, respectively. Although imported before the war, the Confederacy was able to obtain sulfur domestically from private contractors who extracted it from iron pyrites (fool’s gold). Good quality charcoal was also commonly available from the wood of willow or cottonwood trees. For charcoal and sulfur to burn explosively inside a gun barrel, however, a third chemical was needed to supply oxygen. That compound was niter, which was scarce in the Confederacy. The most reliable domestic sources were limestone caves where the nitrates are brought in by water percolating through the soils above the caves and deposited on the floors. Many such caves were in the Southern Appalachians as well as the Ozarks.

Rains visited niter producing caves in Tennessee where he contracted with suppliers to increase production. In order to improve their efficiency, he published a pamphlet explaining how to best excavate the mineral. By October 1861 a Nashville refinery was producing 1,500 pounds daily, which was converted into gunpowder at the nearby Sycamore Mill. When Union troops occupied the region in February 1862, he sent the Sycamore equipment to Augusta, where some of the trained Tennessee workers also relocated.

About half of the 2,900 tons of saltpeter used by the Confederacy during the war was imported. Mines in India could sell it in Liverpool at only one-fifth the cost of the Southern limestone mines, leaving room for considerable profit for blockade runners. As a result, an estimated 30% of blockade runners from Bermuda included saltpeter among their cargos. Consequently, obtaining significant quantities of niter from domestic sources became a high priority and involved the formation of multiple niter beds comprised of compost and urine. As a result, Congress established the Niter and Mining Bureau as a separate organization. It also assumed responsibility for developing domestic sources of other scare minerals and ores, such as lead and copper.

While Rains was pondering a design for the Augusta works he “came into possession of an invaluable pamphlet by. . . the Superintendent of the [British Royal Gunpowder Mills]; in this the entire process and machinery employed at that Factory—the best existing in any country—was succinctly stated”[9]. He worked out a rough sketch, which he gave to architect C. Shaler Smith, recommended by the Tredegar Iron Works. The result would be a massive facility composed of twenty-six widely spaced buildings stretching along the banks of the Augusta Canal for two miles parallel to the Savannah River. It would become the world’s second largest gunpower factory.

The generous building spacing minimized damages from accidental explosions. The design proved its value in August 1864 when a careless smoker caused 18,000 pounds of powder to blow up. Although the blast killed nine people, only one building was destroyed, notwithstanding that windows shook throughout Augusta.[10]

Construction began in September 1861 in the design of a massive assembly line. Raw materials entered the first building and exited the last as finished gunpowder. The most prominent building was the refinery. It resembled the British House of Parliament, including four corner crenellated towers evoking a medieval castle. A 150-foot chimney in the shape of an obelisk, stood in front of the building. The tall chimney, which was a safety feature, is the only original structure remaining today. All flues from the fires used in the refinery were ducted to the chimney where they would be vented high in the air, minimizing the possibility that sparks might ignite flammable material below. The Augusta Powder Works started producing powder in April 1862, only seven months after breaking ground.

Since gunpowder quality depends upon the purity of its ingredients, the refinery was designed to process saltpeter, charcoal, and sulfur to the best possible purity. Saltpeter was boiled, cooled, and crystallized by machinery instead of laborers. Mechanization produced a more uniform quality and was more efficient than labor-intensive methods. Rains could refine up four to five tons of saltpeter a day. Sulfur was purified in a two-step process. First, it was boiled before being poured into wooden containers where impurities sank to the bottom. The top sixty percent in each container was pure sulfur of a bright yellow color when cooled. Charcoal was refined by heating wood for two hours in large iron vats before pulverizing the mixture into a powder in barrels using bronze grinding balls as machinery revolved the barrels.

Dusting is the process of removing the finest particles so that they don’t end up in the bottom of the shipping containers. Powder from the finest grains will burn too fast. Glazing accomplishes two things. First, it reduces the powder’s tendency to adsorb moisture by polishing the outer surfaces of the grains. Second, it makes powder grains less likely to break down into the undesirable dust when transported. Rains and Smith developed a process to glaze the gunpowder with machinery, again optimizing quality compared with manual methods.[11]

Gorgas and Rains became increasingly reliant upon Major (later General) Isaac Munroe St. John for raw materials. After graduating at Yale in 1845 St. John became sequentially a lawyer, newspaperman and a railroad civil engineer. When the war started, he was working for a South Carolina railroad and quickly enlisted as a military engineer. In April 1862 he was placed in charge of the Niter and Mining Corps. He remained supervisor of the operation when it became an independent bureau a year later.

As with niter, the Confederacy had few natural deposits of lead for bullets and copper for cannon barrel alloys, percussion caps and artillery friction primers. It also needed to develop iron ore deposits, which could be mined for cannons and wagon wheels. The richest lead mines in Missouri were occupied by Union forces early in the war. Those in Arkansas and Texas were cut off after Vicksburg fell in July 1863. Thereafter, Virginia was the chief source of mined lead although considerable quantities were imported. An estimated one-third of blockade runners arriving from Bermuda included lead on their cargo manifests. Other supplies came from scavenging battlefields and civilian donations in the form of window weights, lead pipe and cistern linings.

Copper was even more scarce than lead. Mined copper came from southeast Tennessee until Union troops occupied the area in 1864. Thereafter, as a conservation matter, the Confederacy ceased to use the metal as an alloy in cannon metal and allocated it to percussion caps. During the last year of the war copper was scavenged from turpentine stills in the Carolinas. Mercury, required to make the fulminate-of-mercury explosive in percussion caps, had to be imported throughout the war. In one instance the supply of nitric acid required for making the fulminate was exhausted. Consequently, three million caps were sent into the field with a substitute mixture of potassium chlorate and sulfur, but those caps were untrustworthy in damp conditions.[12]

In summer 1862 Gorgas hired chemist John W. Mallet to develop a central weapons laboratory in Macon, Georgia. It was never completed because Gorgas shifted toward a decentralization policy as the war progressed and it became evident that the South’s overworked railroads became an increasingly unreliable distribution system. Nonetheless, the Macon arsenal was a regional producer of cannons, pistols, percussion caps, friction primers and Miniéballs, which were the bullets used by Confederate infantrymen.[13]

On July 30, 1864 a 2,000-man Union cavalry raid under Major General George Stoneman approached Macon. After finding the town defended by “an inexperienced collection of Georgia Reserves, militia and citizen companies”[14] Stoneman turned away. Confederate cavalry attacked Stoneman’s command the next day, taking 700 prisoners. Among the Confederate citizen companies were three composed of Macon’s arsenal and central laboratory workers commanded by Lieutenant Colonel John William Mallett.[15]

Notwithstanding the South’s initial dearth of factories, scarce natural resources, persistent skilled labor shortages and a Union Naval blockade, Josiah Gorgas’s Ordnance Bureau was one of the Confederacy’s success stories. Until the final surrenders, the chief Confederate armies were well supplied with arms and ammunition, although they sometimes could not continue major battles due to inadequate transportation for replenishing such supplies in the field, as at Sharpsburg. At times, Confederate infantrymen were better armed that Union soldiers. When Major General Ulysses Grant captured 60,000 arms at Vicksburg, he declared that many were superior to those carried by his own men. Augusta ended the war with a powder inventory of 70,000 pounds and had produced a total of 2.8 million pounds since it became operational. Similarly, the Ordnance Bureau had produced over 320,000 shoulder arms, chiefly by repairing damaged weapons used in the field. A year before the war ended the bureau was supplying all the weapons and munitions needed by the Confederate armies. When the Army of Northern Virginia surrendered at Appomattox the soldiers had been without food for three days, but each infantryman carried 75 rounds of ammunition.[16]

Union Ordnance

Compared to the Confederacy, the Northern and Union-loyal border states enjoyed considerable industrial capacity. They had 85% of America’s factories and 92% of iron and steel production. The percentage of Northerners involved in agricultural work dropped from 70% in 1800 to 40% in 1860 whereas the same fraction in the South increased from 82% to 84%. New England dominated America’s shipbuilding industry, creating a merchant marine that rivaled Great Britain’s. Notwithstanding that the South produced the feedstock, textile plants in Lowell, Massachusetts operated more cotton spindles than all the eleven Confederate states. More than 80% of America’s small arms manufacturing was centered in the Connecticut River Valley, including the prime military armory in Springfield, Massachusetts. Commercial suppliers included such still-familiar companies as Colt, Remington and Smith & Wesson.

All the Union artillery manufactured during the war was produced by private companies. Most notable among them was the West Point Iron and Cannon Foundry of Cold Springs, New York, which would become the Federal Ordnance Bureau’s largest commercial supplier. Others were Fort Pitt Foundry, Ames Manufacturing, and Phoenix Iron Company. All had proven capabilities, having been founded between 1774 and 1818.[17]

Delaware’s E. I.du Pontde Nemours was America’s biggest gunpowder producer. Founded in 1802, the venerable family partnership provided 40% of antebellum America’s gunpowder. The two other major suppliers were Maine’s Oriental Powder and Connecticut’s Hazard Powder. Despite being in a slave state, du Pont’s managing partners were fiercely Union-loyal. Major peacetime customers included railroad construction contractors and mining operators. In 1860 its government sales were less than 6% of a $750,000 total. Two years later government sales alone approximated $1,200,000. Initially du Pont charged the government $0.18 per pound. Priced peaked at double that amount in September 1864 due to higher costs for raw materials, particularly saltpeter. Nonetheless, when setting prices du Pont “consulted” with other producers, thereby establishing a practice that would lead to the formation of a trust, the Gunpowder Trade Association, in 1872.

Although du Pont had problems maintaining quality as production expanded quickly to meet military needs, the company’s gunpowder was generally the standard by which others were measured. A total of ten explosive accidents killed forty-one du Pont workers during the war and sporadically disrupted output. One blast temporarily cut plant output by half. Despite heavy wartime demands, du Pont continued to innovate. Due to the rising cost of saltpeter, the company began substituting sodium nitrate from Chile in place of India’s more costly potassium nitrate. By inventing a way to make the resulting “soda” gunpowder less vulnerable to moisture, du Pont’s substitution became practical. In 1863 the company also began experiments with “gun cotton” explosives that were nearly smokeless. Without such propellants, future inventions of automatic firearms would be useless.[18]

The Union War Department organized its supply bureaus much like those of the Confederacy diagramed earlier, except that the federals didn’t need a Niter and Mining Bureau. Since the North was not blockaded, it had less incentive to reduce reliance upon imported niter. At the start of the war seventy-year-old Colonel Henry Knox Craig was the Army Chief of Ordnance. During the 1846-1848 Mexican War he served as Chief of Ordnance for General Zachery Taylor’s army that invaded Mexico from Texas. Next, he managed the Harpers Ferry Armory before moving to Washington as Ordnance Chief in 1851. When it became obvious that the country was at war only days after Fort Sumter surrendered, Colonel Craig unwisely took a few days off work due to a temporary illness. His absence greatly annoyed War Secretary Simon Cameron who replaced Craig on April 23, 1861 with sixty-six-year-old Lieutenant-Colonel James Wolfe Ripley who was next in the seniority line. Three months later Ripley was breveted a Brigadier General.

Ripley graduated West Point and was commissioned a Second Lieutenant of Artillery in 1814 at age twenty when the War of 1812 was in progress. He was stationed at Sacketts Harbor on Lake Ontario until 1816, the year after the war had ended. Then he went South to participate in the First Seminole War. While serving under Andrew Jackson, the general rebuked the twenty-three-year-old ordnance lieutenant when Ripley refused to comply with an order that did not reach him through proper channels. Jackson promptly ordered that Ripley should immediately comply or the general would send a guard to hang him from the nearest tree.

In 1832 Ripley got an opportunity to make amends with Old Hickory during the South Carolina nullification crisis. For a few months in late 1832 and early 1833 it appeared that fighting might breakout between South Carolina and the rest of the Union over tariff differences. Ripley happened to be in charge at Fort Moultrie in Charleston harbor at the time. Afterward, Army General in Chief Winfield Scott commended Captain Ripley: “His arrangement for the defense of Fort Moultrie was admirable. No one left a higher reputation . . .”[19]

In 1841 the Army sent Ripley to command its armory at Springfield, Massachusetts. Before he arrived, the facility had been administered by civilians whom the employees did not respect. Ripley gradually restored discipline but some rebellious workers continued to foment dissension. After temporarily shutting the plant for repairs, he refused to rehire the troublemakers and cut wages. In response, the workers hung him in effigy.

In 1848 Ripley was promoted to Lieutenant-Colonel and steadily improved the armory’s productivity until he left in 1854. During his last four years there Ripley achieved one of his chief goals, which was to produce rifles with interchangeable parts between Springfield and Harpers Ferry. Nonetheless, after the armories were returned to civilian management in 1854 the weapon parts produced at the two locations were no longer interchangeable. When his Springfield duty tour ended, the armory was developing the 1855 Model Springfield rifle that would become the Union infantryman’s dominant muzzle-loading rifle during the Civil War.[20]

Although failing to appreciate it, when Ripley became Ordnance Chief shoulder arms were beginning to transition from muzzleloaders to breechloaders, and even repeaters. A muzzleloader-equipped infantryman could fire at best about three rounds per minute, and likely only one or two in the heat of combat. That’s because the arms were loaded through the muzzle one round at a time using paper cartridges and a ramrod in a three-step process.

First the powder-end of the cartridge was torn open, typically with the teeth, and then poured down the barrel. Next the Minié ball was rammed down the barrel with the paper part of the cartridge seated against the powder, using the ramrod pushed from the muzzle. The final step was to position a percussion cap on a nipple with a hole through it connecting to the breech. Pulling the trigger caused a hammer to crush the cap, igniting the powder inside the barrel, which exploded to propel the Minié ball. After firing, the entire sequence had to be repeated before a muzzleloader could shoot a second time. For speed, soldiers typically stood to reload, thereby transforming themselves into bigger targets than if they remained kneeling or lying down.[21]

Despite the numerical dominance of muzzleloaders, breechloaders and repeaters were far superior weapons because they could shoot much faster. Although breechloaders were loaded one shell at a time, their cartridges were designed to obviate the need to load powder and bullet sequentially. While some required a separate percussion cap like the muzzleloaders, others with metal cartridges did not. As a result, instead of firing only two to three bullets per minute, a soldier with a single-shot breechloader, such as the Sharps carbine, could fire eight to ten per minute. The firing rate of repeaters was even higher. The Spencer used a magazine of seven cartridges. Although all seven could be fired in ten seconds, the barrel became overheated at such a pace. However, a Spencer-equipped solider had no difficulty shooting fourteen times per minute.[22]

The table below estimates the number and type of shoulder arms procured by the Union and Confederate armies. As a category, shoulder arms includes rifles and carbines. The latter are shorter versions of the rifle used by cavalry for easier handling. Confederates could only purchase breechloaders via imports, whereas they could rarely buy repeaters at all since the weapons were only manufactured in the Northern states.[23]

If Union leaders had taken breech-loading and repeating arms more seriously after Sumter, they might have won the war in two or three years instead of the four required. According to Confederate General Porter Alexander’s memoirs, “There is reason to believe that had the Federal infantry been armed from the first with even the breechloaders available in 1861 the war would have been terminated in a year.”[24]

As breechloaders and repeaters were gradually adopted in the Union cavalry and mounted infantry, their superiority became obvious to everyone. Midway through the war, at Gettysburg in July 1863, the entire Union Army of the Potomac cavalry corps had breechloaders. That is why Major General John Buford’s division was able to hold off a superior Rebel force for most of the morning of the battle’s first day. Later, Union cavalry Brigadier General James Harrison Wilson, in speaking of repeaters (as opposed to breechloaders in general), said, “There is no doubt that the Spencer carbine is the best fire-arm yet put into the hands of the soldier…Our best officers estimate one man armed with it [is] equivalent to three with any other arm.” [25]

Unfortunately, General Ripley concentrated on maximizing production for the .58 caliber Springfield muzzle loading rifle. He did not permit government facilities to make breechloaders of any type. Thus, the only breechloaders that reached the soldiers were made by private industry. Ripley furthermore encroached upon the capacity for private suppliers to make them by offering manufacturers lucrative contracts to instead make Springfields. At war’s end, the Springfield Armory had produced 802,000 units while commercial companies had manufactured another 670,000. Notwithstanding his focus on maximizing muzzleloader production, more than half of the arms issued to federal soldiers until the fall of 1862 were imports. Among the most important were the British Enfields, which were much like the Springfields. Similar Austrian rifles ranked second behind the Enfields in popularity among the imports.[26]

Breechloader advantages were so obvious that even Ripley agreed they should be the prime cavalry shoulder arm in the form of a carbine for cavalry. John Hancock Hall invented America’s first breechloader in 1811. The military’s first evaluation tests were completed in 1819. Results were excellent and the inspection board wrote: “The advantages of these guns over the common ones now in use …is of great consequence.”[27] By 1836 the Hall appeared to be on its way to becoming the Army’s standard firearm with Ordnance Bureau support. As they are prone to do, however, tradition-bound line officers turned against the Hall. Some said its faster firing rate would promote ammunition wastage and others argued that it was not sufficiently rugged. Even after it went out of production in 1844, however, Ordnance Chief George Talcott still considered it “a valuable” weapon.[28]

By 1848 private firms began to make single-shot breechloaders, of which the Sharps carbine became the most popular. Having worked at the Harpers Ferry Armory, Christian Sharps was familiar with the Hall and convinced of breechloading advantages. Between 1854 and 1857 the Army tested a number of new models but concluded in its 1857 report that muzzleloaders were still better overall. During 1858, however, many mounted units that had been armed with Sharps carbines praised them. A year later Ordnance Chief Henry Craig joined them when he wrote in his annual report, “With the best breech-loading arm, one skillful man would be equal to two, probably three, armed with an ordinary muzzle-loading gun.” His 1860 annual report revealed even more conviction, “ … as certainly as the percussion cap has superseded the flint and steel, so surely will the breech-loading gun drive out of use those that load at the muzzle.”[29]

By the time the Civil War started, Ordnance Bureau policy favored single-shot breechloaders for all mounted units. The then-latest Sharps models were loaded with linen cartridges that contained both powder and ball. Closing the breech tore the rear end of the cartridge, leaving exposed gunpowder in the barrel accessible to the flame of a percussion cap via a hole drilled in the nipple where the cap was mounted. As with the muzzleloader, a trigger pull caused the hammer to smash the cap, which injected flame into the barrel. By the end of the war the Army received 80,000 Sharps carbines and 9,000 Sharps rifles. The carbines were for mounted troops and the rifles for infantrymen.[30]

Although Ripley was amenable to ordering commercial breechloaders for the mounted units, he wouldn’t provide any assistance to help private companies scale their production, nor would he readily consider new inventions. On June 11, 1861, less than two months after replacing Craig, a memo he wrote to War Secretary Simon Cameron reveals his antipathy toward new firearm designs:

A great evil now especially prevalent in regard to arms for the military service is the vast variety of the new inventions, each having, of course, its advocates insisting upon adoption by the Government … This evil can only be stopped by positively refusing to answer any requisition for … new and untried arms and steadily adhering to the rule of uniformity of arms for all troops of the same kind such as cavalry, artillery, and infantry. The U. S. [muzzle-loading] muskets as now made have no superior arms in the world.[31]

Ripley had dug in his heels, especially in opposition to breechloaders for infantry. Although some of his objections were sound, it was often clear that his arguments were merely used to buttress personal prejudice. For example, he complained that the faster firing rate of Spencer and Henry repeaters would encourage soldiers to waste ammunition. He also emphasized the higher cost of breechloaders relative to muzzleloaders. By using such arguments as excuses to decline contracts for breechloaders he delayed the private companies’ motives for tooling volume production lines by a number of months thereby retarding the pace of arms deployment.[32]

When unable to make headway with Ripley, determined officers and private contractors used political connections to force him to order breechloaders. One was Colonel Hiram Berdan who organized two regiments of sharpshooters early in the war. A crack shot himself, Berdan required that all enlistees prove their abilities in target trials. Since many arrived with their own rifles, Berdan and his soldiers quickly gravitated toward the Sharps single-shot breechloader as their preferred rifle.

After Ripley turned them down, President Lincoln visited Berdan’s unit one September afternoon in 1861. Berdan used the opportunity to mention his objections about Ripley, but Lincoln was tight lipped. Then the President watched the regiments perform target practice, which included a pointed challenge by Assistant War Secretary Thomas Alexander “Tom” Scott who had accompanied Lincoln. Specifically, Scott challenged Berdan to hit a human-profiled target nicknamed Jeff Davis in the eye. Berdan fired and sent a soldier to retrieve the target six hundred yards down range. When it arrived at the firing line everybody could see that the Colonel had hit “Jeff’s” eye. Lincoln laughed at Secretary Scott’s discomfort and told Berdan, “Colonel, come down tomorrow, and I will give you the order for the breechloaders.” Nonetheless, Ripley did not order the rifles until January 1862 and Berdan’s men were not fully armed with them until June 1862.[33]

The most effective Ripley circumventer was Christopher Miner Spencer who had two advantages. First, his repeating carbines and rifles were arguably the most significant advance in shoulder arms technology of the era. Instead of loading the rifle one cartridge at a time, his gun used a magazine of seven waterproof metal cartridges, which could sequentially move each unused cartridge into the barrel’s breech with a simple lever action. The same action also ejected the spent cartridge from the previous shot. Second, he promptly used political connections.

At the outbreak of the war, Spencer was a twenty-seven-year-old Connecticut inventor who in March of the previous year had patented his repeating rifle. A lifelong inventor, at age fifteen he built a steam engine and later pioneered machine tools for drop forging. At age eighty-seven, he became absorbed in aviation. For seventeen years, he lived near Mark Twain in Hartford, and the author may have modeled his chief character in A Connecticut Yankee in King Arthur’s Court after Spencer. Like Twain’s fictional character, Spencer worked three years at the Hartford Colt works before hiring on at a silk factory owned by three brothers named Cheney. While employed at the silk factory, he invented the repeater on his own time.[34]

Because Navy Secretary Gideon Wells was a Hartford man and friend of the Cheney family, he arranged for the Navy to test the Spencer two months after the war began. The chief of naval ordnance, Commander John Bernard Adolphus Dahlgren, tested five hundred rounds with only one misfire. Dahlgren was impressed enough to order seven hundred rifles in June 1861.[35]

A couple of months later, Alexander Brydie Dyer of the army ordnance corps tested the Spencer. He fired it eighty times and simulated combat conditions by burying it in sand and saltwater for twenty-four hours. In November, Spencer demonstrated the weapon for General in Chief George Brinton McClellan, who kept his headquarters with the Army of the Potomac. McClellan ordered the Potomac Army’s ordnance chief to evaluate the rifle and prepare a report. The testing officer was favorably impressed. McClellan also asked a board of three other officers, including Major (later Major General) Alfred Pleasanton, who would later command the same army’s cavalry corps, to provide a separate report. Pleasanton and his colleagues gave the Spencer a thumbs-up.[36]

None of the favorable Army evaluations resulted in orders, but they did compel General Ripley to describe his objections. In December 1861, he concluded that the Spencer and competing Henry—that would evolve into the legendary Winchester ’73—were too heavy when fully loaded. He also falsely opined that neither was superior to existing single-shot breechloaders. In sum, he did not “consider it advisable to entertain or accept either [the Spencer or Henry] propositions.”[37]

The Cheney brothers appealed to a few powerful New Englanders who may have been admitted as shareholders into the Spencer Repeating Rifle Company. In addition to the Navy Secretary they included prominent Republican and future presidential candidate James Gillespie Blaine, and Warren Fisher, a Boston financier. Fisher wrote directly to Secretary of War Cameron, who had a reputation for graft. Whatever (if any) backroom deal applied, Ripley ordered ten thousand Spencers the day after Christmas 1861.[38]

By the time Spencers began to be deployed with combat troops in meaningful numbers, the evidence was overwhelmingly in their favor. Major General William Starke Rosecrans, who commanded the Union Army of the Cumberland in Tennessee for about twelve months in 1862–1863, strongly supported repeaters. One of his mounted brigade commanders, John Thomas Wilder, fully agreed. On his own initiative, Wilder wrote to the Henry manufacturer, asking if it would sell repeaters to his troops, which the soldiers would pay for themselves. The manufacturer replied that there was a waiting list. During the wait, Christopher Spencer visited the Army of the Cumberland, where Wilder tested the Spencer with favorable results. Rosecrans was able to get Ripley to send Wilder’s soldiers Spencers in spring 1863.[39]

In June 1863, Rosecrans launched an offensive against General Braxton Bragg’s Confederate Army of Tennessee. Wilder’s Brigade rode quickly ahead of Rosecrans’ army to capture and hold a mountain pass at Hoover’s Gap until a Union infantry corps could be brought up to solidify the position. Wilder’s men did the job on June 25, suffering a total of 62 casualties while inflicting 146. Due to the Spencer’s superior firing rate, the opposing Confederate commander thought he was outnumbered five to one.[40]

Wilder even more convincingly demonstrated the Spencer’s superiority at the Battle of Chickamauga, September 18–20, 1863. Bragg attempted to launch a surprise attack across bridges along Chickamauga Creek in northern Georgia just south of Chattanooga, Tennessee. In preliminary action on the eighteenth, Wilder was guarding Alexander’s Bridge. According to historian Glenn Tucker: “The preliminary affair at Alexander’s bridge, where Wilder with only part of a single brigade and with but four [cannons] of his battery was able to hold off a division with artillery for nearly five hours, was an important milestone in the progress of the war. It confirmed the value in combat of the Spencer repeating rifle.”[41]

The July 1863 Battle of Gettysburg proved to be a turning point in the breechloader versus muzzle-loader contest. In addition to the firepower advantages enjoyed by John Buford’s single-shot breechloader federal cavalry at the start of the battle, George Custer’s Spencer-equipped cavalry convincingly demonstrated the repeater’s advantages on the third day. More importantly, when the victorious Union soldiers scavenged the battlefield after the fight, they collected 24,000 loaded muskets including 18,000 with two or more loads. Some had as many as ten loads. Such errors, nearly impossible with breechloaders, rendered the affected muzzle-loaders useless during combat.[42]

As a result, Christopher Spencer’s next Washington visit got him into the White House. On August 17, 1863 he arrived with a gleaming new Spencer repeater to give the President as a gift. After examining the rifle, Lincoln handed it back to Spencer and asked that inventor disassemble it so that the President could “see the inwardness of the thing.” Next, Lincoln asked Spencer to return at two o’clock the next day prepared for target practice. Together with his son Robert, Lincoln led his personal secretary, John Hay, and Spencer to the Treasury Park, where Lincoln, Spencer and Hay took turns shooting the rifle. Lincoln was impressed enough to replace Ordnance Chief Ripley the next month. At the end of the war, the Spencer Repeating Arms Company and the Burnside Rifle Company, which produced the Spencer carbine under license, held the Ordnance Bureau’s largest contracts.[43]

Although the Spencer was a marked advance in shoulder arms, the Henry evolved into the iconic Winchester ’73 to become known as the rifle that won the west. Benjamin Henry worked for the New Haven Arms Company, owned by Oliver Winchester. When Henry joined it, the company manufactured an unpopular repeater that used poorly designed cartridges. He improved the design to use superior copper rim-fire cartridges. Unlike the Spencer, which held its magazine in the butt stock, the Henry’s sixteen-load magazine extended underneath the barrel. Since few of the rifles and required cartridges had yet been manufactured, Ripley ignored the Henry for over a year. Although it had been tested by the Navy and the ordnance chief of the Army of the Potomac with favorable results, Ripley refused to place any orders. The first Henrys used in combat were purchased by soldiers individually on the commercial market in spring and summer 1862.[44]

Hundreds were sent to Kentucky, where the publisher of the Louisville Journal received one as a gift. He responded by editorializing that one soldier armed with a Henry was equivalent to fifteen using muzzleloaders. By January 1863, knowledge of the Henry’s combat value began to spread beyond Kentucky. Union soldiers used a number of privately-owned Henrys during the Battle of Chickamauga. Although federal orders were small, about six thousand were sold privately to adroit state authorities by the end of the war. As 1864 began, Winchester could sell on the public market all the Henrys he could make, but he could not make many because he was too dependent upon small subcontractors.[45]

After Brigadier General George Douglas Ramsay replaced Ripley as Ordnance Chief in September 1863, the former reported in April 1864 that over 80% of the 110,000 breechloaders and repeaters then on order would be delivered in six months. His report also endorsed metal cartridges, recommending that guns using paper and linen cartridges be gradually removed from service. As for repeaters, he wrote that they “are the greatest favorite with the army … [and] the demand for them is constant … in large quantities.” He urged that the “Spencer Company should be encouraged to produce as many as possible.”[46]

After the sixty-two-year-old Ramsay resigned in September 1864, he was replaced by forty-nine-year-old Alexander Dyer who had given the Spencer a favorable evaluation early in the war. Reversing Ripley’s policy, Dyer wrote in December, “the experience of the war has shown that breechloading arms are greatly superior to muzzleloaders for infantry as well as cavalry.” He urged that the Army form a committee to settle on a single cavalry repeater design and a separate single-shot breechloader infantry design to “be exclusively adopted.” Once the designs were settled, both government and private armories could tool for volume production thereby providing arms at minimal per-unit costs.[47]

Nonetheless, a number of historians defend Ripley’s focus on muzzleloaders. First, they argue that private industry lacked the capacity to deliver breechloaders any faster than the historical record reveals. Second, they reason that Ripley was forced to concentrate on the more commonly available muzzleloaders in order to arm the rapidly growing Union armies as quickly as possible.

Regarding the first point, Ripley defenders fail to consider how he could have helped private breechloading companies more quickly develop volume production lines. First, he might have placed orders sooner thereby enabling the companies to mechanize their production lines earlier, or to subcontract to others. Although admitting from the start that breechloaders were the best cavalry shoulder arms, by the end of 1861 less than half of the 14,000 carbines he purchased were breechloaders. Similarly, less than one percent of the 235,000 infantry rifles were breechloaders. By the end of 1861 the Ordnance Bureau had over one million muzzleloaders on order as compared to only 73,000 breechloaders. Second, at the end of 1861 Ripley had contracted with twenty-two private companies for six hundred thousand .58 caliber Springfield muzzleloaders, thereby preemptively capturing much of private industry’s subcontracting capacity thereby denying it to breechloading companies. Third, the Springfield Armory’s mechanized production knowledge could have been more readily shared with private companies thereby speeding up breechloader production.[48]

As for the Ripley defenders’ second point, the Ordnance Chief could have given more thought to how effectively he was arming the Union soldier as opposed to how quickly. By ordering hundreds of thousands of European muzzleloaders, he violated his own standardization principle, creating the very munitions diversity problem he wanted to avoid. Moreover, the muzzle-loading imports gained him none of the firepower advantages that breechloaders would have provided. Firearms historian Carl Davis writes, “… it is clear that the [breechloaders] increased rate of fire was far more effective in combat than any of the officers opposed to the breechloaders believed that it could be.” Equally important, Ripley failed to appreciate subtle, but important, disadvantages of muzzleloaders. One example, noted earlier, was the battlefield infantryman’s tendency to load them multiple times without firing, thus rendering the gun useless in combat. Similarly, he failed to appreciate the breechloaders’ sturdiness and reliability and instead wrongly assumed them to be delicate compared to Springfields.[49]

Without sacrificing the Ordnance Chief’s preference for muzzleloaders, firearms historian Davis suggests that Ripley might have better handled the breechloader issue by deciding upon “… a private pattern of rifle, say the Sharps, and issued contracts for them to larger private armories. These companies could have paid the Sharps Rifle Company a fee for use of its patent. It would have meant that the major arms companies of the North were producing a standard pattern of service rifle, which, along with the Springfields, would have constituted regulation arms for the infantry service.” This option would not have encroached upon the capacity of the government armories, while only a fraction of private capacity would have been diverted to breechloaders. However, it likely would have resulted in faster breechloader deployment.[50]

Blame for the failure to deploy breechloaders and repeaters more rapidly does not rest entirely upon Ripley. The advantages of the weapons were so obvious from the start that other leaders should have intervened. Lincoln and War Secretary Edwin Stanton (who replaced Cameron in February 1862) could have been more proactive. When Lincoln replaced Ripley with Ramsay in September 1863, Stanton objected because of a personality conflict. Lincoln yielded and Stanton put his own man, George Balch, unofficially in charge of the bureau despite Ramsay’s title. Consequently, Ramsay resigned after a year, accomplishing far less than he had hoped. As noted, only two months after Dyer replaced Ramsay the former made it clear that he wanted all soldiers eventually armed with breechloaders and repeaters.[51]

Even though Republicans were notorious advocates for public works spending and subsidies for private business, there was almost no federal investment in the private arms industry. Instead the relationship between the Ordnance Bureau and manufacturers was often adversarial, with penalties and cancellations for late deliveries. Inventors like Spencer and Henry received no material assistance or even advice about how to scale production. Nonetheless, only five months after receiving Ripley’s first order for repeaters, Spencer had a plant that may have been bigger than any others except for the Government’s Springfield Armory and Colt’s Hartford facility. Yet he still needed help on the production line.[52]

When Lee surrendered at Appomattox in April 1865 the United States Army had not only won the Civil War, it had finished a revolution in arms. The previous month War Secretary Stanton directed that all federal soldiers be issued breechloaders.[53]

- [1] Frank Vandiver, Ploughshares into Swords: Josiah Gorgas and Confederate Ordnance (College Station: Texas A&M Press, 1952), 3, 9-11, 16, 26, 31, 35, 37, 38, 51-54, 66, 106; Mary DeCredico, Encyclopedia of Virginia, “Josiah Gorgas”, https://tinyurl.com/rywmgb9, accessed October 12, 2020; J. W. Mallett, “Work of the Ordnance Bureau; 1861-65,” in Southern Historical Society Papers, Reverend J. William Jones, ed. 37, (January – December 1909), https://tinyurl.com/uet3c5p, accessed October 12, 2020.

- [2] Major Adrian T. Marinez, “Mobilizing the Confederate Industrial Base for Total War,” (Master’s Thesis, U.S. Marine Corps Command Staff College, 2011), 3; Mallett, “Work of the Ordnance Bureau: 1861-65”.

- [3] Caleb Huse, The Supplies for the Confederate Army, (Boston: T. R. Marvin & Sons, 1904), 19-20; Vandiver, Ploughshares, 89; DeCredico, “Josiah Gorgas”; Carl Davis, Arming the Union, (Ft. Washington, N.: Kennikat Press, 1979), 52.

- [4] Webb Garrison, Creative Minds in Desperate Times: The Civil War’s Most Sensational Schemes (Nashville, TN: Rutledge Hill Press, 1997), 91-92; Stephen Wise, Lifeline of the Confederacy (Columbia: University of South Carolina Press, 1988), 96; Merton Coulter, The Confederate States of America: 1861-1865 (Baton Rouge: Louisiana State University Press, 1950), 290, 295; Paul Silverstone, Civil War Navies: 1855-1883 (New York: Routledge, 2006), 49.

- [5] Wise, Lifeline, 95-96; Frank Vandiver, Confederate Brass (Baton Rouge: Louisiana State University Press, 1954),117-9; Clement Eaton, A History of the Southern Confederacy (New York: Free Press, 1954), 133, 145.

- [6] Philip Leigh, Trading with the Enemy, (Yardley, PA: Westholme Publishing, 2013), 13; Virgil Jones, The Civil War at Sea, 3 vols. (New York: Holt Rinehart Winston, 1965, 1961,1962), 3:74-75.

- [7] DeCredico, “Josiah Gorgas”; Vandiver, Ploughshares, 59, 148; Mallett, “Work of the Ordnance Bureau; 1861-65”.

- [8] Vandiver, Ploughshares, 75; Theodore P. Savas, History Net, “Heart of the Southern War Machine” https://tinyurl.com/ueafhr5, accessed October 12, 2020; George W. Rains, “History of the Confederate Powder Works” An Address Delivered by Invitation Before the Confederate Survivors Association, at its Fourth Annual Meeting, on Memorial Day, April 26th, 1882., https://tinyurl.com/weehkj2, accessed October 12, 2020.

- [9] Rains, “History of the Confederate Powder Works”.

- [10] Rains, “History of the Confederate Powder Works”; Savas, “Heart of the Southern War Machine”; Coulter, Confederate States , 205; William H. Hess, , “The Origin of Nitrates in Cavern Earths,” in The Journal of Geology,. 8, No. 2 (Feb. - Mar., 1900), 133; David G. Surdam, “The Union Navy’s Blockade Reconsidered,” in Naval War College Review 51, No. 1 (Winter 1998), 100 https://tinyurl.com/vmhhwcj, accessed October 12, 2020.

- [11] Rains, “History of the Confederate Powder Works”; Savas, “Heart of the Southern War Machine”; Coulter, Confederate States, 207.

- [12] Vandiver, Ploughshares, 106-7; Coulter, Confederate States, 205; Surdam, “The Union Navy’s Blockade Reconsidered”, 100; Mallett, “Work of the Ordnance Bureau; 1861-65.”

- [13] Vandiver, Ploughshares, 112-4; Eaton, History of the Southern Confederacy, 133.

- [14] William Marvel, National Park Service, “Stoneman’s Raid” https://tinyurl.com/yx8ddxjw, accessed October 12, 2020.

- [15] William Marvel, National Park Service, “Stoneman’s Raid” https://tinyurl.com/yx8ddxjw, accessed October 12, 2020; Richard Lobst, Civil War Macon (Macon, GA: Mercer University Press, 2009), 218.

- [16] Rains, “History of the Confederate Powder Works”; Savas, “Heart of the Southern War Machine”; Eaton, History of the Southern Confederacy, 134; Emory Thomas, The Confederate Nation, (New York: Harper Torchbooks, 1979), 210; Paddy Griffith, Battle Tactics of the Civil War, (New Haven: Yale Press, 1989), 77.

- [17] James McPherson, Drawn With the Sword, (New York: Oxford University Press, 1996), 13; “Civil War Overview: North and South,” American Battlefield Trust, https://www.battlefields.org/learn/articles/north-and-south, accessed October 12, 2020; J. G. Randall and David Donald, The Civil War and Reconstruction, (Boston: D. C. Heath, 1961), 11; James McPherson, Battle Cry of Freedom, (New York: Oxford University Press, 1988), 95; Davis, Arming the Union, 85; James Huston, The Sinews of War: Army Logistics 1775 – 1953, (Washington, U. S. Govt. Printing Office, 1966), 186; “Field Artillery,” Civil War Talk, https://tinyurl.com/uf595lp, accessed October 12, 2020

- [18] Harold Hancock and Norman Wilkinson, “A Manufacturer in Wartime: Dupont, 1860-1865,” in The Business History Review 40, No. 2 (Summer, 1966), 213-5, 221-2, 224, 230; Berkeley R. Lewis, “Notes on Ammunition of the American Civil War 1861-1865,” in American Ordnance Association Pamphlet (Richmond, VA: William Byrd Press, 1959).

- [19] Robert Bruce, Lincoln and the Tools of War, (Urbana: University of Illinois Press, 1989), 25.

- [20] Ibid., 23-27, 29.

- [21] Earl J. Hess, The Rifle Musket in the Civil War (Lawrence: University of Kansas Press, 2008), 75.

- [22] Bruce, Lincoln and the Tools, 114.

- [23] Ibid., 54.

- [24] E. Porter Alexander, Military Memoirs of a Confederate (New York: Charles Scribner & Sons, 1907), 53.

- [25] Bruce, Lincoln and the Tools, 101, 290; E. Porter Alexander, Military Memoirs of a Confederate (New York: Charles Scribner & Sons, 1907), 53; Hess, Rifle Musket, 56–57; Edwin Coddington, The Gettysburg Campaign (New York: Charles Scribner & Sons, 1968), 258.

- [26] James Huston, Sinews of War, 186; Bruce, Lincoln and the Tools, 50.

- [27] House of Representatives Documents, Volume 112, 51 https://tinyurl.com/y3bs9a92 accessed, October 12, 2020.

- [28] Davis, Arming the Union, 108-12; Lewis, “Notes on Ammunition of the American Civil War 1861-1865”.

- [29] Ibid., 117.

- [30] Ibid., 115-8; Lewis, “Notes on Ammunition of the American Civil War 1861-1865”.

- [31] Thomas K. Tate, General James Wolfe Ripley, Chief of Ordnance: Answers to His Critics (Privately Published, 2008), 15.

- [32] Davis, Arming the Union, 123-5; Bruce, Lincoln and the Tools, 104-5.

- [33] Gordon L. Jones, Confederate Odyssey: George Wray Artifacts Collection, (Athens: University of Georgia Press, 2014), 326; Bruce, Lincoln and the Tools, 109-11.

- [34] Bruce, Lincoln and the Tools, 113–14.

- [35] Joseph Bilby, A Revolution in Arms, (Yardley, Pa.: Westholme Publishing, 2006),74.

- [36] Ibid., 76–77; Hess, Rifle Musket, 56.

- [37] Bilby, Revolution in Arms, 78.

- [38] Ibid., 78.

- [39] Ibid., 88–90.

- [40] Steven Woodworth, Six Armies in Tennessee (Lincoln: University of Nebraska Press, 1998), 24; Bruce, Lincoln and the Tools, 255.

- [41] Glenn Tucker, Chickamauga (Dayton, OH: Morningside House, 1992), 115.

- [42] Bruce, Lincoln and the Tools, 100.

- [43] Ibid., 261-3; Davis, Arming the Union, 123-5.

- [44] Bilby, Revolution in Arms, 64–67.

- [45] Ibid., 94, 130–2; Jack Coggins, Arms and Equipment of the Civil War (New York: Fairfax, 1962), 35–36.

- [46] Davis, Arming the Union, 140.

- [47] Bilby, Revolution in Arms, 198.

- [48] Davis, Arming the Union, 124; David Hounshell, From the American System to Mass Production, (Baltimore: John Hopkins Press, 2014), 45.

- [49] Davis, Arming the Union, 130.

- [50] Ibid., 142.

- [51] Terry Jones, Historical Dictionary of the Civil War (Lanham, MD: Scarecrow, 2011), 1173.

- [52] Davis, Arming the Union, 92.

- [53] Hess, The Rifle Musket, 56.

If you can read only one book:

Davis, Carl. Arming the Union. Ft. Washington, NY: Kennikat Press, 1979.

Vandiver, Frank. Ploughshares into Swords: Josiah Gorgas and Confederate Ordnance. College Station: Texas A&M Press, 1952.

Books:

Bilby, Joseph. A Revolution in Arms. Yardley, Pa.: Westholme Publishing, 2006.

Bruce, Robert. Lincoln and the Tools of War. Urbana: University of Illinois Press, 1989.

Coggins, Jack. Arms and Equipment of the Civil War. New York: Fairfax, 1962.

Garrison, Webb. Creative Minds in Desperate Times: The Civil War’s Most Sensational Schemes. Nashville, TN: Rutledge Hill Press, 1997.

Griffith, Paddy. Battle Tactics of the Civil War. New Haven: Yale Press, 1989.

Hancock, Harold and Norman Wilkinson. “A Manufacturer in Wartime: Dupont, 1860-1865,” in The Business History Review 40, No. 2 (Summer, 1966), 213.

Hess, Earl J. The Rifle Musket in the Civil War. Lawrence: University of Kansas Press, 2008.

Hess, William H. “The Origin of Nitrates in Cavern Earths,” in The Journal of Geology 8, No. 2 (February - March 1900), 133.

Hounsell, David. From the American System to Mass Production. Baltimore: John Hopkins Press, 2014.

Huse, Caleb. The Supplies for the Confederate Army. Boston: T. R. Marvin & Sons, 1904.

Huston, James. The Sinews of War: Army Logistics 1775 – 1953. Washington, D.C.: Office of the Chief of Military History, 1966.

Jones, Gordon L. Confederate Odyssey: George Wray Artifacts Collection. Athens: University of Georgia Press, 2014.

Jones, Virgil. The Civil War at Sea, 3 vols. New York: Holt Rinehart Winston, 1965, 1961,1962.

Leigh, Philip. Trading with the Enemy. Yardley, PA: Westholme Publishing, 2013.

Lewis, Berkeley R. “Notes on Ammunition of the American Civil War 1861-1865,” in American Ordnance Association Pamphlet. Richmond, VA: William Byrd Press, 1959.

Lobst, Richard. Civil War Macon. Macon, GA: Mercer University Press, 2009.

Marinez, Adrian T. “Mobilizing the Confederate Industrial Base for Total War”, Master’s Thesis, U.S. Marine Corps Command Staff College, 2011.

McPherson, James. Drawn with the Sword New York: Oxford University Press, 1996.

Randall, J. G. and David Donald. The Civil War and Reconstruction. Boston: D. C. Heath, 1961.

Tate, Thomas K. General James Wolfe Ripley, Chief of Ordnance: Answers to His Critics. Privately Published, 2008.

Thomas, Emory. The Confederate Nation. New York: Harper Torchbooks, 1979.

Wise, Stephen. Lifeline of the Confederacy. Columbia: University of South Carolina Press, 1988.

Organizations:

No organizations listed.

Web Resources:

Loading and Firing a Civil War Musket.

The Spencer Carbine.

Weapons of the Civil War Cavalry: The Sharps Carbine.

America’s first Metallic Cartridge: The Burnside Carbine.

Mary DeCredico, “Josiah Gorgas (1818-1883),” in Encyclopedia Virginia.

J. W. Mallett, “Work of the Ordnance Bureau; 1861-65,” in Southern Historical Society Papers, Reverend J. William Jones, ed. 37, (January – December 1909).

Theodore P. Savas, “Heart of the Southern War Machine: The Augusta Powder Works was an Unparalleled Accomplishment of Military Industry,” History Net.

“History of the Confederate Powder Works” An Address Delivered by Invitation Before the Confederate Survivors Association, at its Fourth Annual Meeting, on Memorial Day, April 26th, 1882.

David G. Surdam, Review “The Union Navy’s Blockade Reconsidered,” in Naval War College 51, No. 1 (Winter 1998).

William Marvel, “Stoneman’s Raid,” National Park Service.

“Civil War Overview: North and South,” American Battlefield Trust.

“Field Artillery,” Civil War Talk.

Other Sources:

No other sources listed.